Part pairing is an increasingly common practice used by manufacturers of smartphones and other electronic products to control who can and can’t perform certain types of repairs. It is made possible by serialisation of spare parts. Here is how it works: some parts have a unique serial number, which is paired by manufacturers to an individual unit of a device using software. If any of these parts need replacing during a repair, they might not be accepted, or lose some of their functionality unless remotely paired to the device again via software by the manufacturer. This approach could create major barriers to independent and self repair as we explain in a recent blog post.

To find out more about this issue, in July we hosted a webinar with contributions from Alexandre Isaac, founder of the Repair Academy, Marie Castelli, Back Market public affairs manager and Thomas Opsomer, repair policy engineer at iFixit and member of the European Right to Repair Campaign’s Steering Group.

Panelists shared a lot of interesting insights on the threat posed by part pairing to repairers and what policymakers should do about it.

A threat to independent repair

While serialisation of spare parts is not a new practice, manufacturers have started using it as a new barrier to independent repair.

Independent repairers have been noticing an increase in parts that can not be replaced because they are paired to a specific device via software thanks to their serial number, or if they can be replaced, they risk losing functionality and hinder the performance of the product. Meanwhile, “authorised” repairers, part of the manufacturers’ network, have access to the tools needed to bypass this issue and are therefore not affected.

Part pairing seriously limits the extent of work independent repairers and refurbishers can perform on a device in a way that allows them to earn a living. In some cases, very talented repairers perform very complex operations to reuse a sensor from an otherwise defective part, in order to prevent part-pairing problems.

“Microsoldering for instance is one way to deal with part pairing but it’s very technical and complicated and having to spend several hours microsoldering just to repair a screen or a camera is not what we call repairable”.

Alexandre Isaac

To address this issue amongst others, Apple, the manufacturer currently using part pairing the most in smartphones and tablets, has created an “independent repair provider” program to include independent repairers in its network and allow them access to genuine spare parts and the tools to deal with part pairing. But from a business point of view, there are many downsides in joining the program, from limited repairs allowed to unannounced audits, mandatory sharing of customer information, cost of parts and the ban on using 3rd party parts.

From a refurbisher’s perspective, it’s even more complicated. Not only has part pairing the potential to destroy the industry, there’s no “fall back” solution as programmes such as Apple’s do not involve refurbishers.

A source of anxiety for consumers

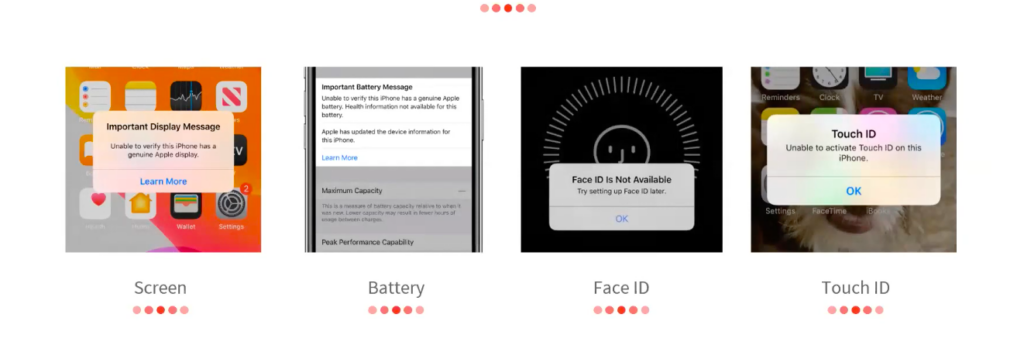

Once a device subject to part pairing is repaired or refurbished by an independent professionals, customers risk seeing warning messages like the ones below (shared by Alexandre Isaac in his presentation) appear to inform them that the new part “isn’t genuine” and even sometimes that it’s not working.

Understandably, this generates stress and mistrust from consumers for repairers who worked on their devices. Backmarket, a leading platform of refurbished products – and a member of the European Right to Repair campaign, has noticed an increase in aftermarket services tickets since the rise of products affected by part pairing.

According to Marie Castelli, public affair manager at Backmarket: “even when explained that these messages are mainly a warning message and do not affect the functionality, we see a share of customers returning the product”.

Alexandre Isaac from the Repair Academy confirms there is a serious risk in consumers losing trust in repair businesses because of the error messages and the functionality losses. This would not only affect the repair industry and lead to loss of jobs, we would also see an increase in the amount of electronic waste discarded every year and new products being purchased.

The way forward

At European level, an Ecodesign regulation for smartphones is currently underway and a provision on part pairing is included in the current draft. According to Thomas Opsomer, we need to improve its wording to make sure such practice does not hinder independent repair.

“If we don’t stop it at the smartphone level which is a very iconic product, it risks trickling down to other products.”

Thomas Opsomer

In the electronic sector, there are various ways for independent repairers to find spare parts: they can either be new genuine parts when manufacturers agree to sell them, original parts from other devices from the manufacturers (what’s called cannibalization) or aftermarket parts (new third party parts). Today, most parts used by repairers are good quality third party parts imported from Asia that are sold at an affordable price and can be purchased in advance. For repairers it makes more sense financially than to purchase original parts when they’re available as they’re more affordable.

Unfortunately, all of these options could be disabled by part pairing unless manufacturers are required to allow independent repairers to complete repairs with all kinds of spare parts.

How could we address this issue?

The automotive sector has clearer regulation. The “motor vehicle block exemption regulation” defines original spare part as “part produced to original specifications” meaning any part as long as they’re technically compatible with the product. This means independent repairers have the right to purchase and use any part they want and warranty can not be voided.

“It would be extremely beneficial to have a similar regulation for electronics” said Thomas Opsomer.

When it comes to security – , an argument often used by manufacturers to justify stricter control on repair via part pairing – a simple solution could be to store authentication key on the main logic board instead of a peripheral component and/or temporarily disable the authentication function of the component to be replaced until the user has authenticated via other means. For example, a user wouldn’t be able to reuse finger print or face identification on a new screen, but could authenticate in a different way (e.g. with pin code) before resetting other forms of authentication. This would remove the need for part pairing and give more control to consumers.

To achieve this, we urgently need laws to address this issue.

As explained by Marie Castelli, “This year is a crossroad as the share of serialised products is growing on the market and we’ll see the impact in a few years on refurbished products”.

Alexandre Isaac who’s seen a recent expansion of part pairing to laptops added: “everything that is electronic today could be serialised and this threatens the future of repair”.

In order to achieve a future where repair is as accessible as possible, we’ll keep fighting against this software-related threat and continue to bring it to the attention to European policymakers working on the Right to Repair.

If you’d like to support us in this mission, you can join or donate to the campaign!